Advitech is proud to introduce our new Machinery Safety Services, designed to help you comply with AS 4024 and ensure the safety of your machinery and operations.

Our team of TÜV-certified engineers brings extensive expertise in risk assessment, system design, verification, and validation to deliver comprehensive safety solutions tailored to your specific needs.

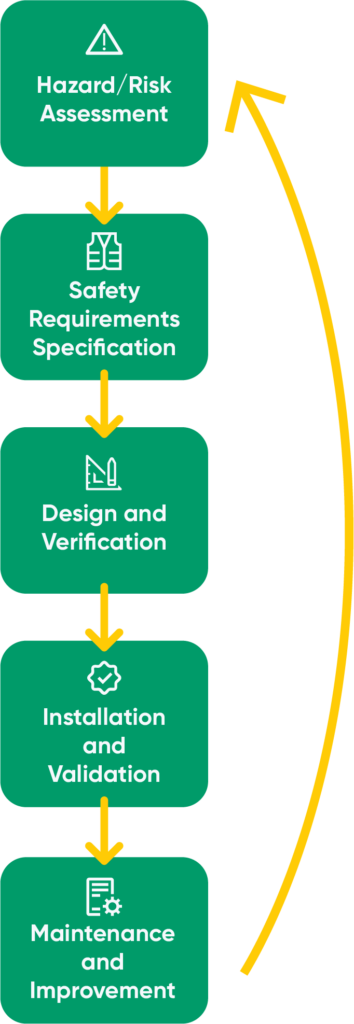

Our Machinery Safety Services follow a structured safety lifecycle approach to maximise productivity and improve safety:

- Hazard/Risk Assessment: Identify hazards and estimate associated risks to prioritise mitigation efforts.

- Safety Requirements Specification (SRS / SFRS): Evaluate safeguarding options and select appropriate mitigation techniques.

- Design and Verification: Design system architecture, document safety circuit design, and procure necessary materials, ensuring compliance with relevant standards.

- Validation: Ensure systems operate within defined parameters and comply with applicable standards through rigorous testing and validation.

- Maintenance and Improvement: Regularly verify that system requirements are met and perform preventative maintenance and upgrades as needed.

Safety Risk Assessments

Safety risk assessments are a critical step in identifying potential hazards and ensuring compliance with standards and regulations. Our TÜV-certified engineers use a methodology based on the most current international standards to provide assessments that help you make informed decisions to enhance the safety of your employees and operations.

Design and Verification Services

Our design services support the development of comprehensive safety systems, including the creation of Safety Functional Requirement Specifications (SFRS) and Safety SISTEMA Verifications. These services ensure that safety devices are correctly applied and compliant with the specified Performance Level (AS 4024.1503).

Validation Services

Our validation services confirm that safety systems are properly installed and perform to standards. These services include safety circuit analysis, machine stop time services, normative conformance audits, and safety system validation.

Compliance with Type C Standards

Our services ensure compliance with Type C standards, including:

- AS 4024.3301 /ISO 10218-1: Safety requirements for industrial robots.

- AS 4024.3101 Materials cutting – Milling machines (including boring machines) – Safety requirements.

- AS/NZS 2153.1 /ISO 4254-1: Safety requirements for agricultural machinery.

- AS 1473: Safety requirements for woodworking and wood processing machines.

By expanding our services to include these machine safety solutions, Advitech enhances its client offerings, improves safety outcomes, and increases operational efficiency. Contact us today to learn more about how we can help safeguard your operations.